Seit 1988 - CGTech steht für Erfahrung, Tradition

und zukunftssichere Technologien

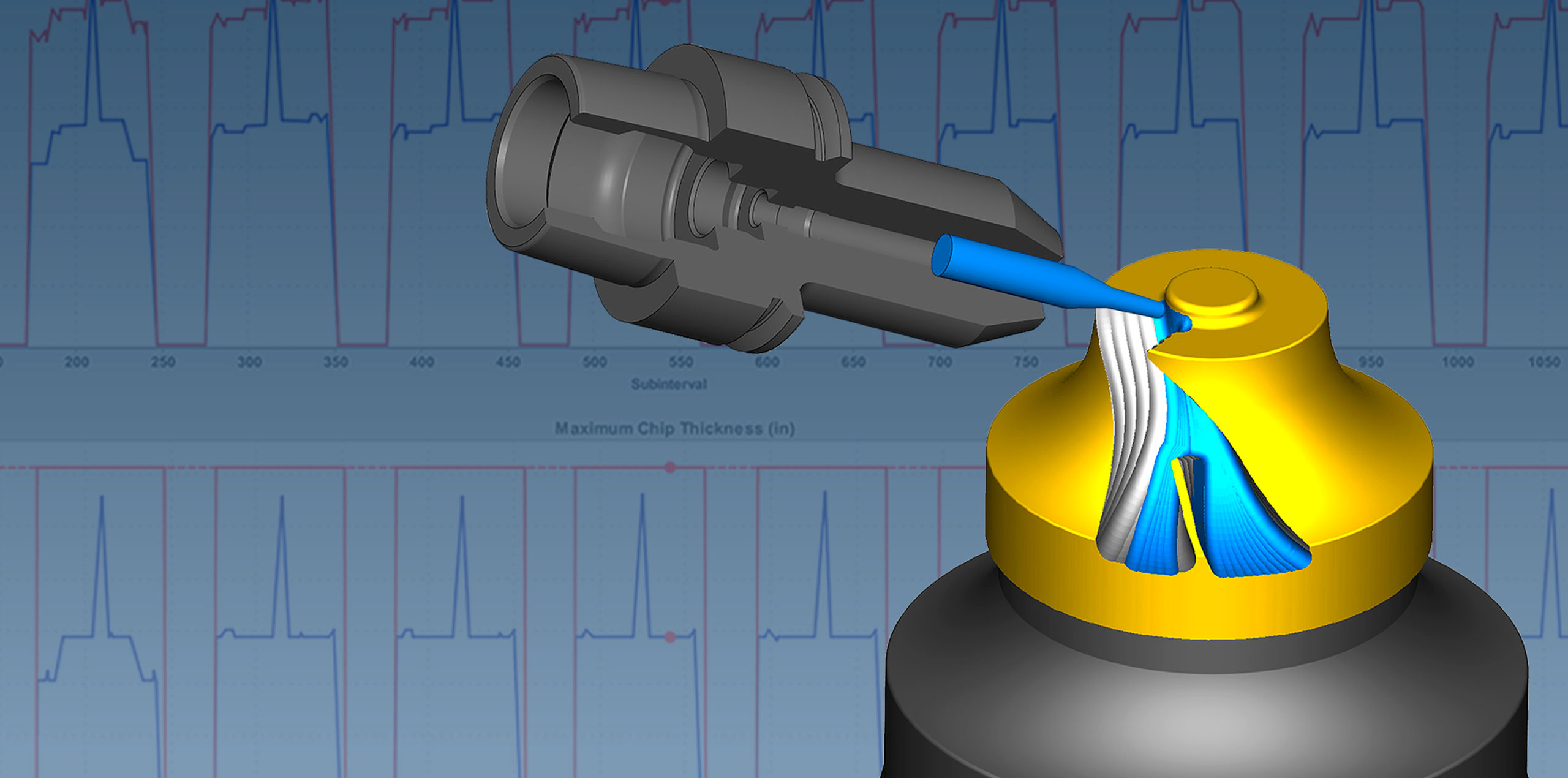

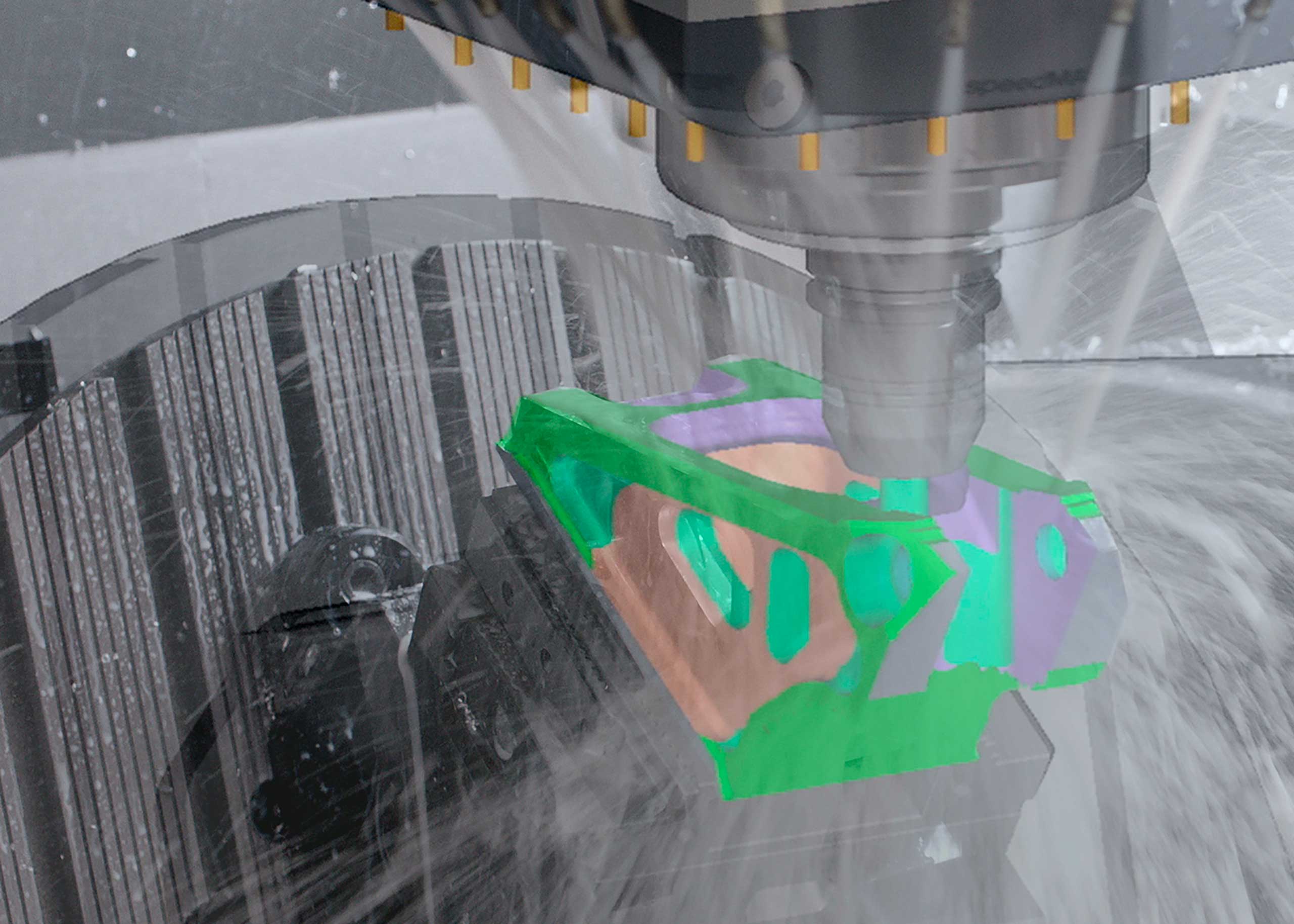

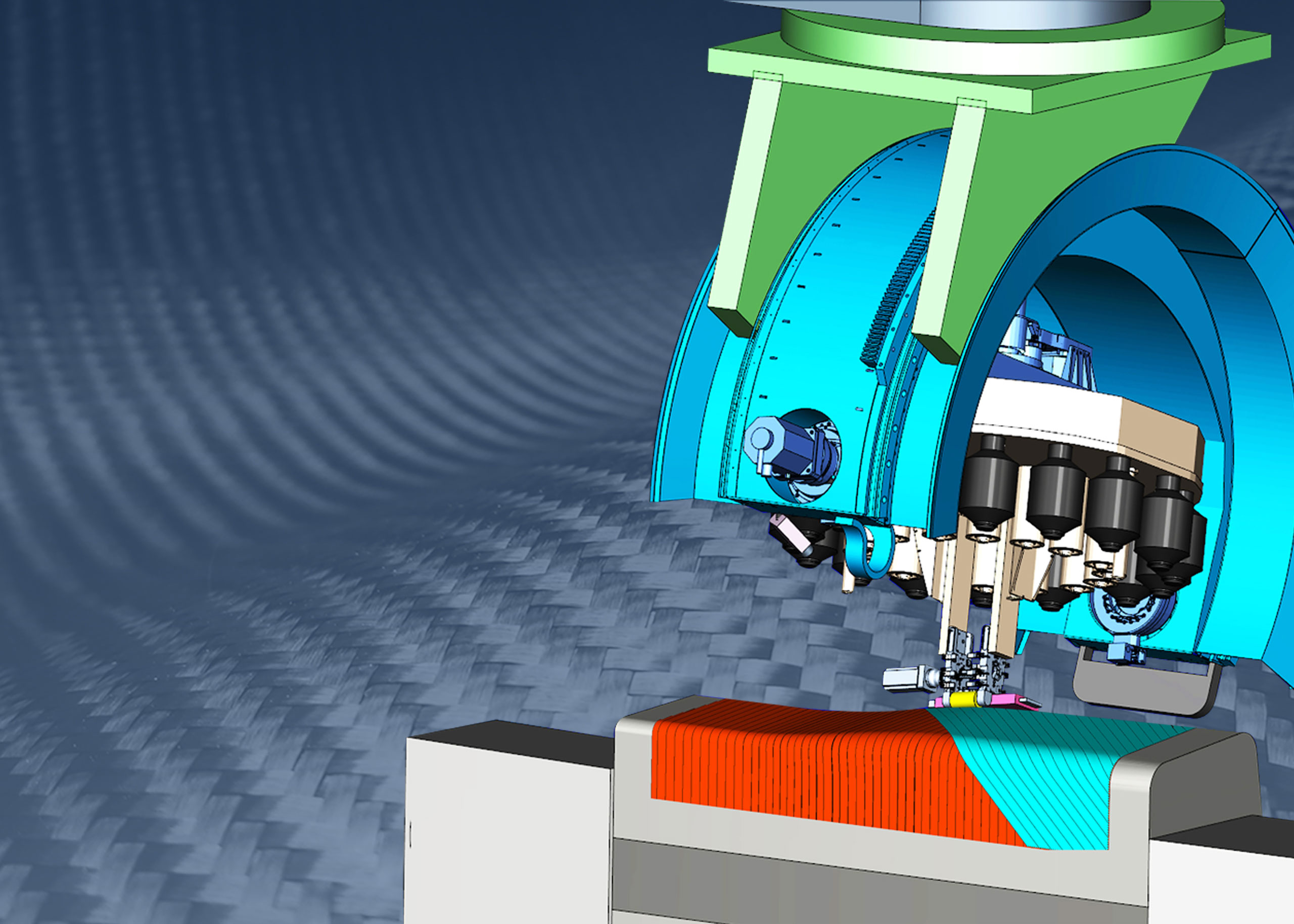

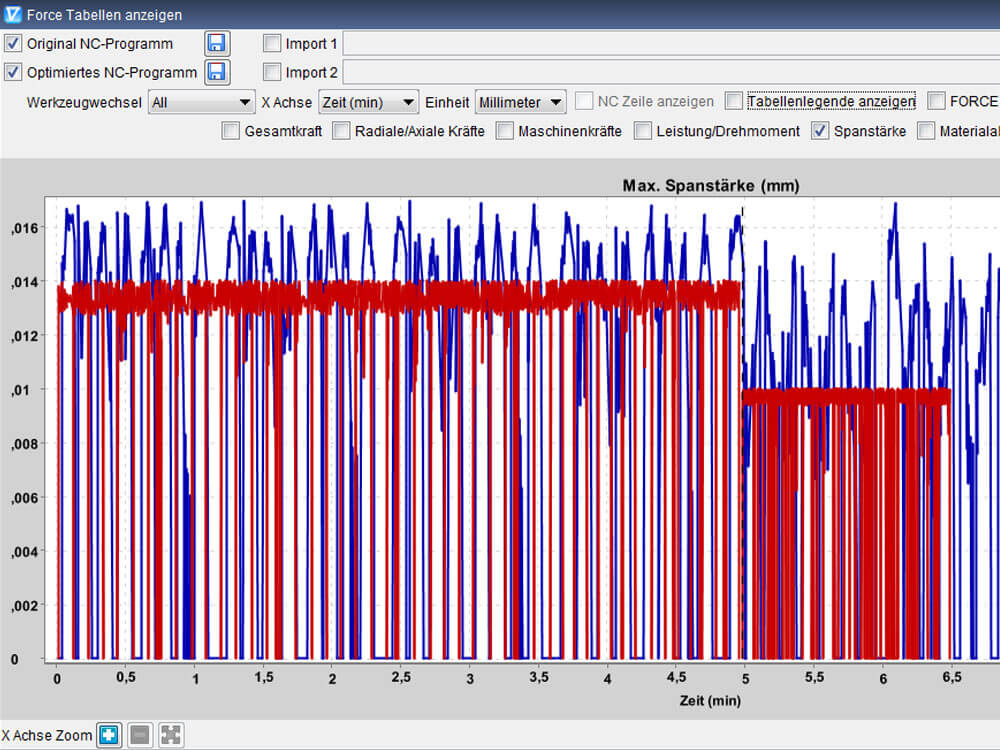

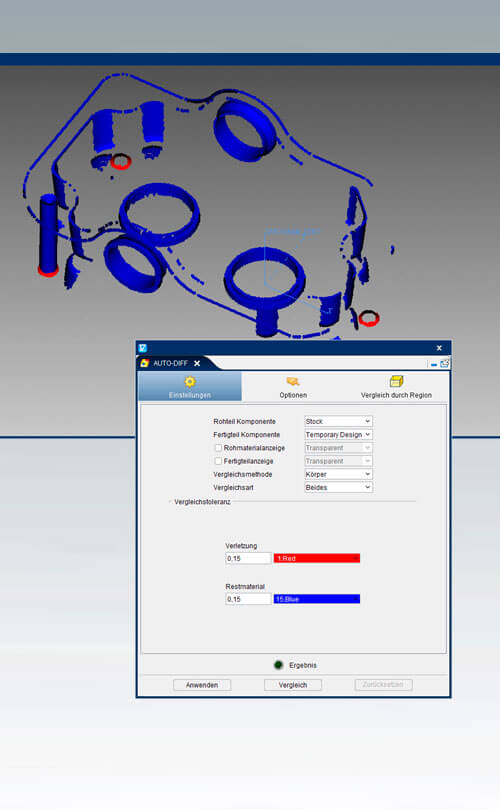

Seit 1988 ist CGTech mit VERICUT der weltweite Marktführer im Bereich NC-Code Simulation. Wir bieten ein breites Angebot an Produkten und Lösungen für ihre CNC Maschinen, um Kollisionsfrei und effizienter zu fertigen. Wir arbeiten eng mit unseren Kunden und Partnern auf der ganzen Welt zusammen, um ihre Bedürfnisse zu verstehen und geeignete technische und wirtschaftliche Lösungen durch den Einsatz fortschrittlicher Technologien anzubieten.

Produkte

Media & Presse

Service & Support

Unternehmen

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan